Vegetable oil is the oil that extracted from various types of oilseeds, oil plants, fruits, grains, and some nuts. The most popular used vegetable oils are soybean oil, canola oil, coconut oil, corn oil, cottonseed oil, olive oil, palm oil, palm-kernel oil, peanut oil, sunflower oil and sesame oil. Vegetable oil is used to add flavor, assist with texture, and to cook food. As the demand for edible oil quantity and quality keep growing year after year, more and more interested in setting up a small vegetable oil plant that can not only full fill the demands of the market but also cater to yourself daily oil consumption need. if you have a farm, you also need a small oil press line that you can sell the oil squeezed by your own oil plants.

☆Start this small oil plant you only need very low investment. Setting up a small oil business, you only need a very low budget, even need only one or two-room building. Unlike the large-scale oil pressing factory, the plant is easy to install, commission and operate. The small oil plant is also can cater to the need of the regional market. The business demands very low investment since the machinery is very cheap and you can set it up in two very small room. So, a small scale oil plant is very profitable opportunity for startup entrepreneurs.

☆If you build a small-scale oil plant, you will have access to some huge tax benefits. Also, many small-scale oil plants qualify for government incentive and concessions. Don’t forget to research about what tax benefits and other incentives you may be eligible for.

☆Financial independence is probably the most important reason you get into the oil processing business. And that is a great thing? Everybody wants financial independence. However, you explain financial independence-unlimited cash, old age security and the capacity to buy whatever you want.

☆If you build a small-scale oil plant, you will have access to some huge tax benefits. Also, many small-scale oil plants qualify for government incentive and concessions. Don’t forget to research about what tax benefits and other incentives you may be eligible for.

☆Financial independence is probably the most important reason you get into the oil processing business. And that is a great thing? Everybody wants financial independence. However, you explain financial independence-unlimited cash, old age security and the capacity to buy whatever you want.

The Equipment You Need In Small Oil Plant

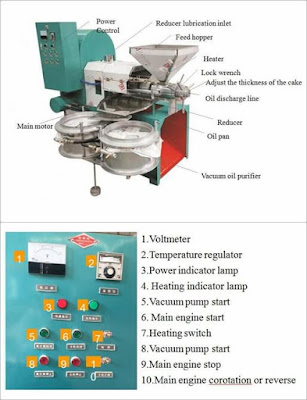

Different oil processing equipment will be used according to different plant seeds you are going to press. In all the equipment, the oil press machine is the key part in the complete small oil plant, no matter what raw oil seeds, the oil press machine is indispensable, you can choose a automatic screw oil press or hydraulic oil press according to the oil seeds you are going to press. In addition to the oil press, you need a oil seed roaster. In oil press processing, most oil seeds need to be roasted to press more thoroughly and get high oil yield, such as cotton seeds, peanuts, sesame, castor, sunflower, etc.. After the oil pressing, the oil refining equipment you also need for the small oil plant. One refinery means a series of refining processes to remove FFA, gums, waxes, phospholipids and free fatty acid, pigment, off-flavor and other impurities in the oil to make it purifier for edible uses.

Small Oil Plant Supplier

Zhengzhou Double-lion Grain & Oil Milling Machinery Co., Ltd. is dedicated to oil press machine design & manufacturing. Cooperating with Henan University of Technology,it has carried out the new technological research and application of oil machinery, screw oil press machine, integrated oil press machine, hydraulic oil press machine, soybean oil press machine, sesame oil press machine, rapeseed oil press machine, palm oil press machine, etc., and transformed the latest scientific achievements into productive forces to obtain good social and economic benefit. Many foreign friends have established a long-term cooperative relationship with us.

Need guidance to start an oil press machine business? Please contact us, our engineer will give you professional guidance and suggestion.

Type: automatic oil press, screw oil press, integrated oil press, hydraulic oil press, sesame oil press machine, peanut oil press machine, rapeseed oil press machine, palm oil press machine. Get in touch with us.

How to Get in Touch with Zhengzhou Double lion Flour Mill Manufacturer

Email: ada@zzdoubleion.com

Whatsapp:+8618937672012 (Ada)

Wechat:+8618937672012 (Ada)

Add:Lotus street NO.100,Hi-tech development zone, Zhengzhou, Henan, China.