What should you do to keep your automatic oil press running smoothly? Know more about your automatic oil press, the structure, the working principle, when it is working properly or when it needs attention. You can extend oil press life and maximize your investment after you read this article.

1.Full Automatic Oil Press Structure and Working Principle

(1)Structure

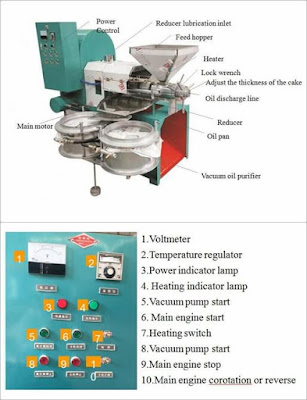

This series oil press machine mainly consists of automatic control part, heating and pressing part, adjusting part, driving part and vacuum refining part.

A.The automatic control part consists of air switch, alternating current contactor, temperature controller, automatic circuit protection device.

B.Heating & pressing part consists of heater, pressing bolt, cage bars, and the body assemble.

C.The driving part consists of main shaft, reducer box, belt pulley, and motor wheel.

D.Adjusting part has adjusting screw, adjusting nut, hand shank, and lock nut.

E.Vacuum refining part has vacuum pump and oil filter drum line.

(2)Working principle

When the oil press machine working, the oil crops come into the press chamber through the feed-in part. The press screw keep squeezing and make the oil crops move forward and be pressed. Since the oil crops is in the state of motion, so it can cause a high temperature in the press chamber. On the other hand, due to the pressing screw root diameter is gradually thickening while the pitch is gradually reducing, so that when the pressing screw is rotated, the oil get pressed out from the crops. And the cakes are pressed out of the end of the press screw. The oil flows out to the oil pan, then flow to the vacuum refining part. The vacuum pump begin to work and the vacuum bottle is no air inside. The oil flows through the refining cloth and into the bottle. The dregs quarantined in the refining cloth.

2. Full Automatic Oil Press Installation

(1)When installation, the surrounding need to leave enough space for the staff to operate.

(2)First, adjusting the four bolts under the bottom of the machine, make the machine a horizontal position. Then, adjusting the refining bottle to horizontal position.

3.Operating and Using

(1).Before use, you must carefully read the instructions, familiar with the performance characteristics of the machine and operating methods.

(2).Before starting, we must fully check the machine, such as fasteners, handle, pulley, the running parts, filling 20# oil in the reducer.

(3).Loosen the lock nut, counter clockwise rotation adjustment screw, counter clockwise rotation, the cake outlet gap will narrow; clockwise rotation adjusting handle, the cake gap will widen. The cone screw close to the cone ring cake, then screw the adjusting screw clockwise (spin 3-5 circles), then tighten the nut, ready to start the machine.

(4).Machine connected three-phase flour wire power supply, after the power is switched on, spindle should be rotated counter clockwise, regardless of any situation, machine must have a good grounding device, otherwise can not start the machine.

(5).Regulating temperature controller. We need to adjust the temperature to the oil temperature of 120℃ and 160℃(according to the oil), the heating switch to the host heating position, machine heating, at this time the green light of the temperature controller, red light goes out, when the machine temperature reaches the set temperature, red light green light goes out, the temperature of the machine is automatically controlled and maintained at the set temperature, when the temperature is low in winter, the heating switch to the host all the heating position, the oil temperature rise, facilitate the smooth flow of oil/

(6).Press the button on the main motor, host start running, the direction of rotation is counter clockwise rotation.

(7).New press for 4-8 hours test machine, methods:with dry oil cake material from the hopper feed slowly, repeated press, polish the press, Note:do not put the material directly into the new machine hopper, put a small amount of oil seed into the feed inlet, to prevent pressing screw shaft clogging. If you put too much oil seeds in one time, abnormal noise in the press chamber or pressing screw plug, should stop the machine immediately, eliminating obstruction, or reassembly and then start grinding.

(8). Hot smoke from the cake out let should be discharged from the pipe. Extracts the hot cake to have to spread out promptly, don’t rush into a pile or into a bag, otherwise it will produce natural phenomena. When the continuous working time is longer, the machine temperature is too high, we should take measures to cool down the machine temperature such as :fan etc..

(9).When oil flows into the vacuum filter, press the button of the vacuum pump, vacuum pump begins to run, the air in the oil filter is drawn out, inner pressure of oil filter barrel, the oil is pumped into filter, the residue was isolated in cloth, to be squeezed, open the valve on the oil filter, stop the operation of the vacuum pump, the filtered oil flows out of the valve at the bottom of the vacuum filter.

(10).Shutdown procedure:first stop feeding, and then put a small amount of cake crumbs, waiting to be squeezed out of the chamber, there is no cake from the cake out let. After shutdown the adjustment screw clockwise rotation 1-3 circle,disconnected the power supply.

4.Full Automatic Oil Press Maintenance

(1).Lubrication should be checked after 50 hours of work, the gear box can not be short of oil, adjust screw hole often add butter.

(2).The parts that need to be applied to the lubricating oil should be prevented from entering the dust and other impurities, reducer oil need to be replaced at least once a year.

(3).When the machine output is reduced, the cake or out of the oil is not normal, you need to check the pressing screw, pressing strip, the ring of out cake wear condition, and timely replacement.

(4).When finished oil, should remove the residual cake in the machine, wipe clean machine surface dust and grease.

The automatic oil press supplied by Zhengzhou Double-lion Grain & Oil Machinery Co., Ltd can be used to press oil seeds of peanut, rapeseed, sesame, sunflower, castor, flax, walnut, soybean and some other oil seeds. This is the oil press performance of different oil seeds:

| Material | Oil press rate(%) | Cookie thickness(mm) | Residual oil rate(%) |

| Sesame | 42-55 | 1.0-1.5 | ≤7 |

| Peanut | 40-50 | 0.8-2.0 | ≤8 |

| Rapeseed | 28-38 | 1.0-1.5 | ≤8 |

| Oil sunflower seed | 28-35 | 1.2-1.5 | ≤8 |

| Soybean | 10-16 | 0.8-1.5 | ≤7 |

| Flax seed | 33-40 | 0.8-1.5 | ≤7 |

| Cotton seed | 11-25 | 1.0-2.0 | ≤6 |

| Walnut | 42-52 | 0.8-1.5 | ≤6 |

| Camellia seed | 26-38 | 1.0-2.0 | ≤6 |

Zhengzhou Double-lion Grain & Oil Milling Machinery Co.,ltd. is dedicated in oil press machine design & manufacturing. Cooperating with Henan University of Technology,it has carried out the new technological research and application of oil machinery, screw oil press machine, integrated oil press machine, hydraulic oil press machine, soybean oil press machine, sesame oil press machine, rapeseed oil press machine, palm oil press machine, etc., and transformed the latest scientific achievements into productive forces to obtain good social and economic benefit. Many foreign friends have established long-term cooperative relationship with us.

Need guidance to start a oil press machine business? Please contact us, our engineer will give you professional guidance and suggestion.

Type: automatic oil press, screw oil press, integrated oil press, hydraulic oil press, sesame oil press machine, peanut oil press machine, rapeseed oil press machine, palm oil press machine. Get in touch with us.

How to Get in Touch with Zhengzhou Double lion Flour Mill Manufacturer

Email: info@zzdoublelion.com

Whatsapp: +8613849022317 (Sophia)

Wechat: +8613849022317 (Sophia)

Add:Lotus street NO.100,Hi-tech development zone, Zhengzhou, Henan, China.

How to Get in Touch with Zhengzhou Double lion Flour Mill Manufacturer

Email: info@zzdoublelion.com

Whatsapp: +8613849022317 (Sophia)

Wechat: +8613849022317 (Sophia)

Add:Lotus street NO.100,Hi-tech development zone, Zhengzhou, Henan, China.

没有评论:

发表评论